-

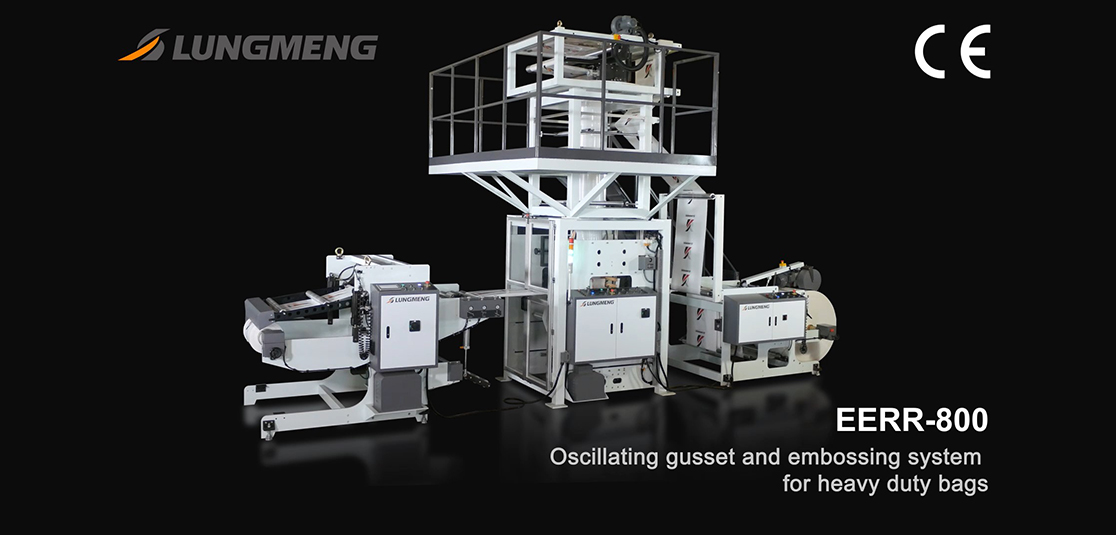

The machine is designed for turning the printing position to the expected location, completing the embossing & gusseting functions on tube film, winding on jumble roll which will be used to make heavy duty material bags iate. the machine cossts of unwinder, embossing & gusseting unit with rotating device and a rewinder.

-

Unwinder: mother roll max. width 800mm, max. dia. up to 1000mm, with tension control device and EPC.

-

Embossing & rotating facility: the tube film is inflated by filling air and be post-gusseted at both sides, embossing by needles plate forming touchable outward knurls which can prevent slippery during stacking & transportation.

-

It has a rotary facility at top of the main unit, the device can turn the tube film at max. 80 degrees, rotating the ready printing content desired position, therefore the printing can be seen at the location of gussets at both sides.

-

Rewinder: max. dia up to 1500mm on 6" air shaft with excellent tension control by the servo motor.

-

The EERR-800 can be in-lined with extruder. printing machine as well as sealing & cutting bag making machine for making final products of heavy duty material bags.

-

The finished product width range 450 - 750mm, film thickness 100-400mic., Machine speed 10~60 M/min. gusset depth: 25-125mm.